Training the Next Generation: CNC Machining Education and Career Paths

As the manufacturing industry evolves, CNC machinists are in high demand. Discover the educational paths, essential skills, and career opportunities shaping the next generation of precision manufacturers.

July 10, 2025

Share:

Introduction

As the manufacturing industry continues to grow, the demand for skilled CNC (Computer Numerical Control) machinists is on the rise. CNC machining plays a vital role in producing precision parts for industries such as aerospace, automotive, healthcare, and consumer goods. With the advancement of technology and automation, the field requires individuals with specialized skills and knowledge.

However, the industry is facing a skills gap. As experienced machinists retire, there is a pressing need to train and develop the next generation. CNC machining education provides the technical expertise and practical skills necessary to meet the evolving demands of the industry. This blog explores CNC machining education, the career paths it offers, and how aspiring professionals can build a successful future in this field.

The Importance of CNC Machining Education

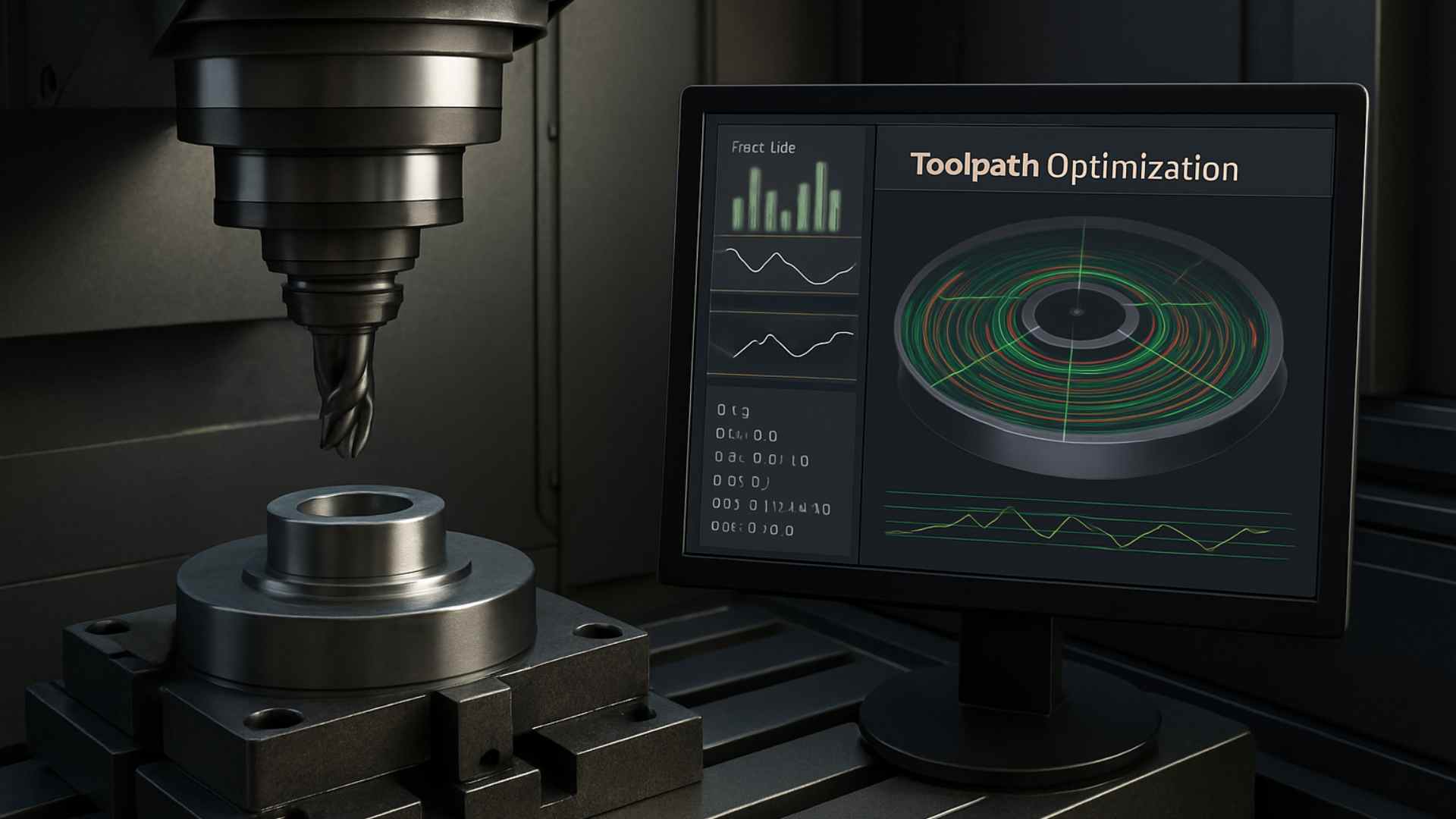

CNC machining is no longer limited to simply operating machines. Modern machinists are expected to have a thorough understanding of programming, CAD/CAM software, and precision engineering. This makes formal education and hands-on training essential for success.

One of the primary reasons CNC education is so important is the industry’s growing complexity. With advancements like AI-powered CNC systems, machinists need to adapt to new technologies. Educational programs equip students with the skills to handle complex machinery, troubleshoot issues, and optimize production processes.

Furthermore, CNC education helps address the skills shortage in the manufacturing sector. By training more individuals in CNC operations, programming, and machine maintenance, educational institutions help bridge the gap between industry demand and the available workforce.

Pathways to CNC Machining Education

There are several educational routes individuals can take to pursue a career in CNC machining. These range from short-term certification programs to full-fledged college degrees.

Technical Schools and Vocational Programs

Technical schools and vocational institutes offer focused programs in CNC machining. These programs typically cover core skills such as G-code and M-code programming, machine setup, blueprint reading, and CAD/CAM operations. They provide hands-on experience with CNC machines, preparing students for entry-level roles in the industry.

Most technical programs can be completed in six months to two years, leading to a certificate or diploma. These credentials demonstrate technical proficiency and help students gain employment as CNC operators or entry-level machinists.

Community College and Associate Degrees

For those looking for a more comprehensive education, community colleges offer associate degree programs in CNC machining or manufacturing technology. These programs combine theoretical knowledge with practical skills. Students learn about CNC operations, advanced machining techniques, and manufacturing principles.

Associate degree programs often take two years to complete. They provide a well-rounded education, which can lead to more advanced roles in programming, quality control, and manufacturing supervision.

Apprenticeship Programs

Apprenticeships offer a combination of classroom instruction and on-the-job training. This model allows individuals to earn a salary while gaining practical experience. Apprentices work alongside experienced machinists, learning the intricacies of CNC operations, troubleshooting, and maintenance.

Apprenticeship programs typically last three to four years. Upon completion, participants earn a journeyman certificate, making them qualified for higher-level positions in the industry.

CNC Certifications

Certifications are an excellent way for individuals to demonstrate their skills and increase their employability. Organizations like the National Institute for Metalworking Skills (NIMS) offer industry-recognized certifications in CNC programming, milling, and turning. Other certifications, such as Mastercam or Haas CNC, validate proficiency in specific software or machine operations.

Certifications are valuable for both entry-level machinists and experienced professionals looking to advance their careers. They provide formal recognition of skills and can enhance job prospects.

Essential Skills for CNC Machinists

CNC machining requires a combination of technical expertise, problem-solving abilities, and attention to detail.

Technical skills include programming CNC machines using G-code and M-code, setting up tools, and operating CAD/CAM software. Machinists must also be proficient in blueprint reading and measuring parts with precision instruments such as calipers and micrometers.

Problem-solving skills are equally important. Machinists often encounter issues with machine performance, tooling, or material inconsistencies. The ability to troubleshoot and make precise adjustments is essential for maintaining production quality.

Attention to detail is critical in CNC machining, as even small deviations can lead to defects. Machinists must ensure that parts meet specifications and maintain consistent quality throughout the production process.

Career Paths in CNC Machining

CNC machining offers diverse career opportunities, with growth potential in various industries.

- CNC Machine Operator: This entry-level role involves loading materials, operating CNC machines, and ensuring parts meet quality standards. Operators monitor the machining process and make basic adjustments.

- CNC Programmer: CNC programmers write the code that controls CNC machines. They use CAD/CAM software to create programs, define cutting paths, and optimize tool movements. Programmers play a crucial role in improving efficiency and reducing waste.

- CNC Machinist: Machinists are skilled professionals responsible for setting up and operating CNC machines. They interpret blueprints, select appropriate tools, and ensure that finished products meet specifications.

- Manufacturing Engineer: This advanced role involves designing and optimizing manufacturing processes. Engineers work on improving machine efficiency, integrating automation, and ensuring product quality.

- CNC Instructor or Trainer: Experienced machinists can transition into educational roles, teaching CNC skills to students in technical schools or industry training programs. This role involves developing course materials, conducting training sessions, and mentoring aspiring machinists.

The Future of CNC Machining Careers

The future of CNC machining is shaped by technological advancements such as AI, machine learning, and IoT integration. Automated CNC systems are becoming more common, enhancing efficiency and reducing the need for manual intervention.

However, this does not diminish the need for skilled machinists. Instead, it creates opportunities for professionals with expertise in CNC programming, robotics, and process optimization. As the industry evolves, CNC machinists with knowledge of advanced technologies will be in high demand.

The growing emphasis on precision manufacturing, particularly in aerospace, healthcare, and electronics, ensures that CNC machining will remain a stable and lucrative career path for years to come.

Conclusion

CNC machining offers rewarding career opportunities with strong growth potential. Through formal education, apprenticeships, and certifications, individuals can develop the skills needed to succeed in this high-demand industry. With the ongoing advancements in automation and precision manufacturing, CNC machinists with specialized expertise will continue to be highly valued in the job market.

Explore Related Machines from Sahil Machines:

FAQ

CNC machining is a manufacturing process that uses computer-controlled machines to shape and cut materials with high precision.

No, but formal education through technical schools or certifications can significantly improve job prospects and earning potential.

It typically takes between six months and two years, depending on the program and whether it’s a certificate, degree, or apprenticeship.

Key skills include programming, machine setup, blueprint reading, and proficiency with CAD/CAM software.

Yes, there is a high demand for CNC machinists, particularly as experienced workers retire and the need for precision manufacturing grows.

Follow Us:

Latest Posts

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.