How AI-Driven CNC Machines Are Enhancing Manufacturing Precision

AI-powered CNC machines are transforming modern manufacturing with smarter, more precise operations. Learn how artificial intelligence improves tool wear prediction, real-time error correction, and adaptive machining.

July 09, 2025

Share:

Introduction

The advent of Artificial Intelligence (AI) in Computer Numerical Control (CNC) machining is revolutionizing the manufacturing industry. Traditional CNC machines, which once operated on pre-programmed instructions, are now integrating AI algorithms to enhance precision, optimize efficiency, and reduce errors. This transformation is making manufacturing processes smarter, faster, and more reliable.

In this blog, we will explore how AI-driven CNC machines are improving manufacturing precision, the key benefits they offer, real-world applications, and future trends in this evolving field.

What Are AI-Driven CNC Machines?

AI-driven CNC machines incorporate machine learning (ML) and data analytics into traditional CNC systems. This integration allows the machines to:

- Learn from data over time

- Optimize tool paths dynamically

- Predict and prevent errors

- Improve adaptive machining capabilities

- Provide real-time monitoring and adjustments

By using AI algorithms, CNC machines can automatically refine their operations, improving precision and efficiency with minimal human intervention.

How AI Enhances Precision in CNC Machining

AI is transforming CNC machining by enhancing its accuracy and consistency. Here are some ways AI contributes to improved precision:

1. Predictive Tool Wear Monitoring

One of the major factors affecting precision in CNC machining is tool wear. Over time, tools degrade, which can lead to inaccuracies.

- AI algorithms continuously monitor tool conditions using sensor data.

- They predict wear patterns and recommend tool changes before the quality deteriorates.

- This prevents errors caused by worn-out tools, ensuring consistent precision.

2. Real-Time Error Detection and Correction

- AI-powered CNC machines are equipped with machine vision and real-time analytics.

- They detect microscopic deviations from the desired dimensions.

- The machine automatically adjusts its parameters to correct the error mid-process.

- This ensures tight tolerances and flawless end products.

3. Adaptive Machining

Traditional CNC machining relies on pre-set parameters, which can be limiting. However, AI-driven systems offer adaptive machining capabilities:

- The machine adapts to material variations by analyzing real-time data.

- It makes dynamic speed and feed adjustments for optimal precision.

- This results in better surface finishes and dimensional accuracy.

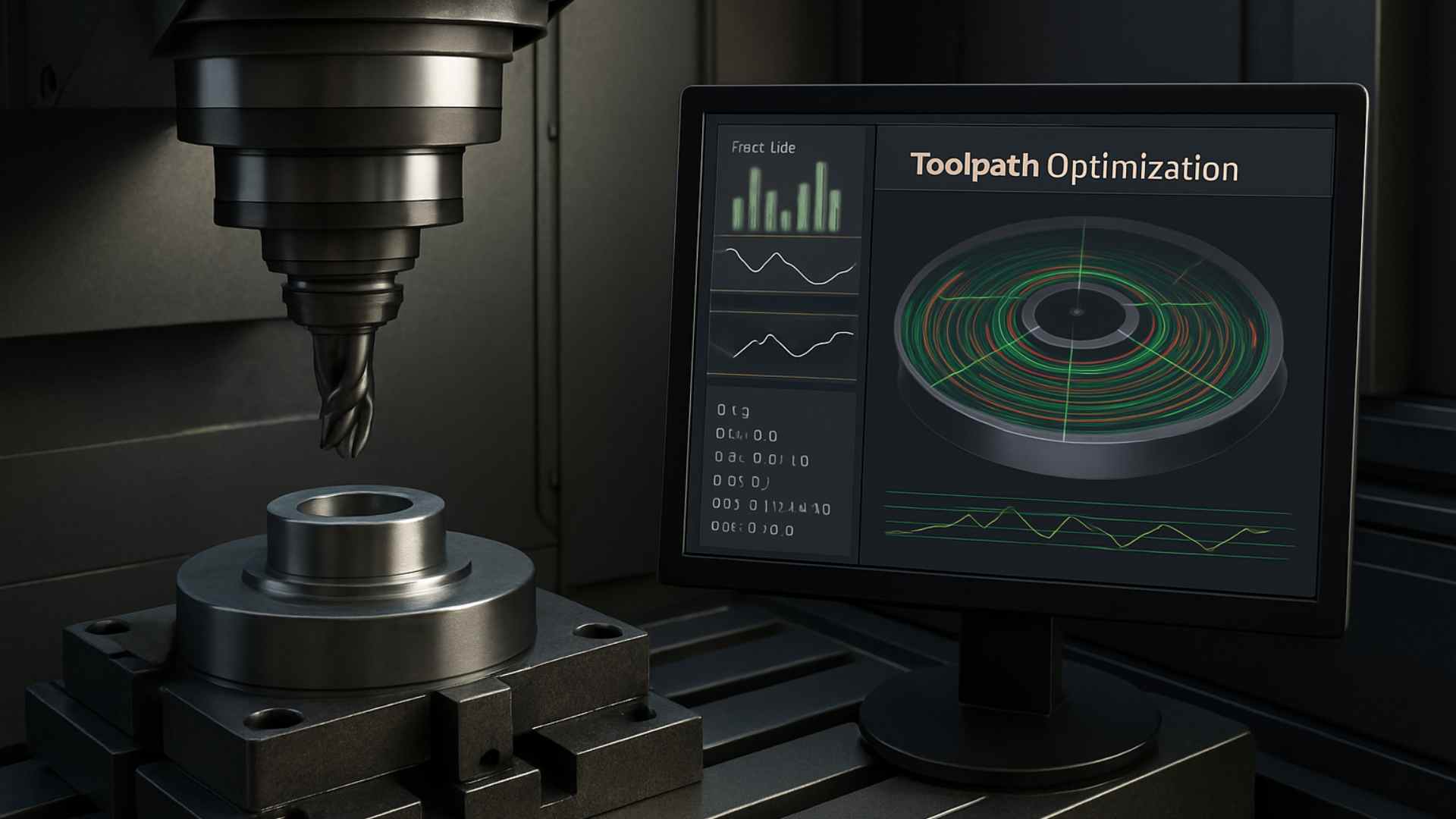

4. Smart Path Optimization

- AI algorithms analyze toolpath data and optimize the cutting paths to minimize material waste and reduce cycle times.

- Smart path optimization ensures smoother cutting motions.

- It reduces vibrations and enhances the overall accuracy of the cuts.

Benefits of AI-Driven CNC Machines

The incorporation of AI in CNC machining offers numerous benefits that significantly enhance manufacturing precision and efficiency:

1. Higher Accuracy and Consistency

- AI reduces human intervention and the possibility of human error.

- With machine learning capabilities, CNC machines can:

- Maintain consistent accuracy over long production runs

- Identify and correct subtle deviations automatically

2. Reduced Downtime

- AI-based predictive maintenance identifies potential issues before they cause breakdowns.

- This reduces unplanned downtime.

- Machines remain in optimal working condition, enhancing overall productivity.

3. Faster Production Cycles

- By optimizing tool paths and feed rates, AI-driven CNC machines reduce cycle times.

- This leads to faster project completions.

- It increases the overall throughput without compromising precision.

4. Improved Quality Control

- AI-powered CNC machines continuously monitor and analyze quality metrics.

- Real-time quality checks detect issues early.

- This minimizes scrap rates and ensures consistent output quality.

5. Data-Driven Insights

- AI generates valuable production insights by analyzing large volumes of data.

- Manufacturers can identify process inefficiencies.

- They can make informed decisions to enhance overall machining performance.

Real-World Applications of AI-Driven CNC Machines

1. Aerospace Industry

- Precision is crucial in aerospace manufacturing, where components must meet strict tolerance requirements.

- AI-driven CNC machines produce high-precision parts with minimal deviation.

- They reduce errors, ensuring reliable and safe aircraft components.

2. Automotive Industry

- AI CNC machines are widely used for manufacturing engine parts, transmission components, and custom parts.

- Real-time monitoring ensures parts meet exact specifications.

- Improved precision leads to higher vehicle performance and safety.

3. Medical Device Manufacturing

- Medical devices require micron-level accuracy.

- AI-driven CNC machines ensure flawless production of surgical instruments, implants, and prosthetics.

- This guarantees consistency and quality in medical products.

4. Electronics Manufacturing

- The electronics industry demands precision machining of small, delicate components.

- AI-driven CNC machines enhance micro-machining accuracy.

- They reduce material waste and improve component reliability.

Challenges in Implementing AI in CNC Machining

While AI-driven CNC machines offer immense benefits, there are certain challenges manufacturers face during implementation:

1. High Initial Investment

- The cost of integrating AI technology into CNC machines is significant.

- This may be a barrier for small and medium-sized enterprises (SMEs).

- However, the long-term ROI often justifies the investment.

2. Complex Integration

Integrating AI requires:

- Software upgrades

- Training models with large datasets

- Skilled personnel for calibration and maintenance

3. Data Security Concerns

- AI-powered CNC machines rely on data exchange between systems.

- Ensuring cybersecurity and protecting sensitive manufacturing data is critical.

The Future of AI in CNC Machining

As AI technology continues to evolve, its role in CNC machining will expand further:

- Self-learning CNC systems: Machines will become more autonomous, requiring even less human intervention.

- Enhanced predictive analytics: Advanced AI algorithms will improve error detection and correction.

- AI-powered cloud integration: CNC machines will leverage cloud computing for better data analysis and remote monitoring.

Conclusion

AI-driven CNC machines are transforming the manufacturing landscape by enhancing precision, reducing waste, and improving productivity. As AI technology continues to evolve, CNC machining will become even more accurate, efficient, and reliable. Companies that adopt AI in their CNC workflows will benefit from greater consistency, reduced costs, and improved quality—ensuring they stay ahead in an increasingly competitive industry.

Explore Related Machines from Sahil Machines:

FAQ

AI-driven CNC machines use artificial intelligence and machine learning algorithms to enhance precision, optimize tool paths, and reduce errors.

AI enhances precision by predicting tool wear, detecting and correcting errors in real time, and dynamically adjusting tool paths.

Yes, they have a higher initial cost due to advanced hardware and software requirements. However, the increased efficiency and reduced waste lead to significant cost savings over time.

Industries such as aerospace, automotive, electronics, and medical device manufacturing extensively use AI-powered CNC machines.

Follow Us:

Latest Posts

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.